4 Common Modes of Vapor Compression Refrigeration

Author:Corun Date:2018/07/12

Vapor Compression Refrigeration uses latent heat produced in the phase transformation of refrigerants, by the way of compression, condensation, throttling and evaporation to reach the target of cooling, which is now the most widely used refrigeration method.

Compressor: intakes the refrigerant vapor from the evaporator, compresses it to the condensation pressure, and then press it into the condenser.

Condenser: condensing the high pressure refrigerant steam from the compressor into liquid, In the process of condensation, the heat released from the refrigerant steam is taken away by the cooling water or air.

Throttle valve/Expansion Valve: when the refrigerant liquid passes through the throttle valve, the pressure decreases from condensation pressure to evaporation pressure, and some of the liquid flashes into vapor.

Evaporator: the refrigerant liquid after throttling evaporates into gas in the evaporator and absorbs the heat of the cooled object, and the cooled object can be a liquid refrigerant or air.

Corun will talk about 4 commonly seen modes in vapor compression refrigeration along with their advantages and disadvantages:

1. Screw Compressor Refrigerator

Advantages: small volume, light weight, simple structure, less vulnerable parts, high reliability, small change of machine torque, less vibration and smooth operation, can withstand certain liquid shock, energy can be steplessly adjusted, high compression efficiency, low exhaust gas temperature and good air tightness.

Disadvantages: the surface of the rotor parts is curved and the machining accuracy is high. A large oil separator is needed to separate the oil from the injection machine and the auxiliary equipment is complex.

2. Centrifugal Compressor Refrigerator

Advantages: high performance coefficient, large cooling capacity; light weight and small volume for units with same unit power; easy to realize multistage compression and throttle; high automation degree; it can automatically adjust the cooling capacity steplessly by import guide vane or frequency conversion, and have a wide adjustment range; has less refrigerant oil mixed with refrigerant and little influence to the heat conductivity effect of the heat exchanger.

Disadvantages: high revolving speed, suitable for large flow situation, not suitable for situations requiring small refrigerating capacity; the inherent surge issue in the case of low load has not been effectively solved.

3. Piston Compressor Refrigerator

Advantages: the earliest type; the heat efficiency is high with high speed; the multi cylinder and energy is adjustable; suitable for various refrigerants, easy to manufacture, low price and easy to operate and manage.

Disadvantages: complex structure, more vulnerable parts, short maintenance period, large inertia of reciprocating motion, discontinuous gas transmission, fluctuating exhaust pressure and large vibration of equipment; suitable for low cooling capacity.

4. Scroll Compressor Refrigerator

Compared with Piston Compressor Refrigerator, it has the characteristics of high efficiency, low noise, less spare parts, light in weight, small in size, energy-saving and small vibration.

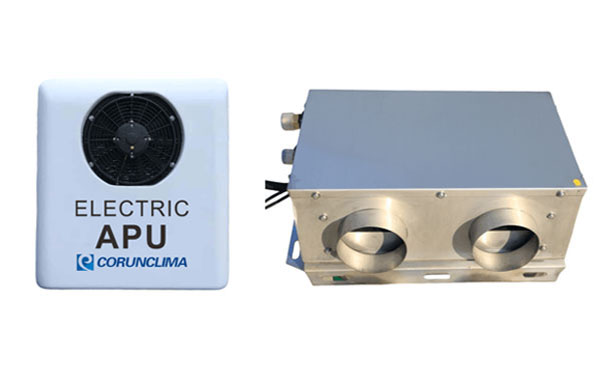

Based on different traits of different modes, Corun chooses just right compressor for different products. For all battery driven products, scroll compressor is used; while for engine driven products, screw compressor is used. Together with Corunclima, let’s enjoy the comfort brought by worry-free transport refrigeration unit and air-conditioning system for trucks, vans, and various types of vehicles!

TAG: Refrigeration Corunclima

Prev Article:Truck Parking Project Could Help Drivers Find Spaces

Next Article:Continental Shows Off Advanced Transportation Technology

.png)