7 Challenges in Refrigerated Transportation

Author:Corunclima Date:2017/08/17

How prepared are you if something goes wrong with the refrigerated freight you’re carrying? A new white paper indicated, “7 Key Challenges in Refrigerated Transportation,” addresses issues such as hot loads, equipment failure, driver error, late notification, post-incident paper trails, regulations compliance and the lack of remote control.

Temperature-controlled freight carriers work in a rapidly changing work environment due to new FSMA rules, more discerning customers, increasing complexity of reefer units and rising cargo values.

The result is that reefer complexity, driver error and late notification from dataloggers leave transportation organizations wide open to the potential for rejected loads, insurance claims, contract loss and reputational damage. This white paper helps carriers understand the key challenges – and offers solutions on how to address them.

Challenge No. 1: Avoiding hot loads

According to the white paper, industry analysts estimate that 32% of refrigerated cargo loaded onto refrigerated vehicles is at the wrong temperature at the time of loading. “The loss of temperature typically happens as a result of poor loading practices,” the white paper states. Many times, cargo is left sitting too long on the loading dock, and the carrier runs the risk of the load being rejected by the receiver.

Transport refrigeration units are not designed to alter the temperature of the cargo; they are designed to maintain the cargo at the loaded temperature.

Challenge No. 2: Equipment failure

If transport refrigeration unit fails, the sensitive cargo is at risk. According to the whitepaper, modern refrigeration units can have more than 200 alarm/fault codes, which could threaten the ability to maintain the temperature of the cargo being transported.

Challenge No. 3: Driver error

Drivers must be required to set the mode of operation of the unit to either continuous run or start/stop mode. Drivers also need to perform manual defrost of the refrigeration unit when required, Blue Tree added.

“However, transport refrigeration units are both complex and different,” according to the white paper. “To perform these basic configurations, drivers must be familiar with the operation of the controller of the refrigeration unit. This poses a big challenge to carriers in terms of driver training. It also exposes them to risks of driver mistakes when operating the equipment.”

Challenge No. 4: Late notification

Saving a load when something goes wrong or fails requires real-time data, immediate notification and identification of the cause and prioritization of the issue, according to the white paper.

“You cannot rely on the driver to detect a fault immediately as it occurs,” the whitepaper indicated. “The driver has little visibility to the controller of the transport refrigeration unit of a trailer or draw bar trailer when on the move.”

Challenge No. 5: Immediate proof of delivery

According to the white paper, when something goes wrong, the carrier is often the first to be blamed. Carriers may end up needing to prove the conditions in which the cargo has been transported; compliance, auditing and documentation are required every step of the way.

Challenge No. 6: Complying with regulations

The FDA’s Food Safety Modernization Act shows that the temperature controls distribution and logistics industry are moving toward more stringent rules, reporting and record-keeping, the white paper mentioned.

“Transportation companies will be impacted significantly by the implementation of the new rules during 2015 and through 2016,” The whitepaper indicated. “Carriers of temperature-sensitive goods will need to develop and implement procedures to describe how they will comply with provisions for temperature control and how they will provide this information to both shippers and receivers on demand. Drivers will need to be trained on temperature management, and reporting requirements and temperature records for each shipment will need to be retained.”

Challenge No. 7: Lack of remote control

Drivers may find it difficult to monitor, analyze and fix temperature problems in compartmentalized vehicles and multi-temperature and multi-zone loads, the white paper said. Instead, the paper suggests, control from the dispatch office without involving the driver may be a more effective solution.

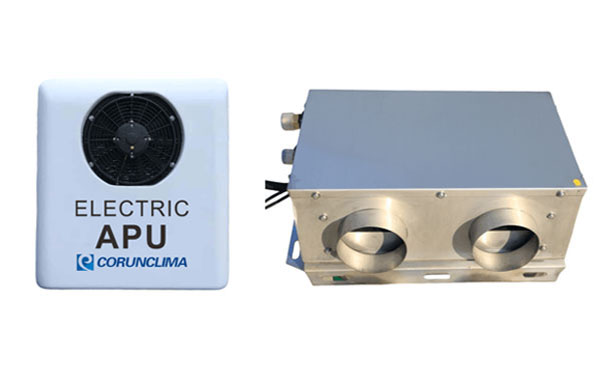

Corunclima All Electric Van Refrigeration Unit C150TB for Gallery

You are also welcome to Corunclima on Facebook & Google+!

Zhengzhou Corun. Tech. Co. Ltd., & Corunclima

With nearly 20 yrs’ exp. in R&D and manufacture in transport refrigeration unit and all-electric air conditioner, Corunclima gradually evolves from manufacturer to professional consultant of eco-friendly, cost-effective, customizable transport cooling solution.

.png)