Four Main Components in Refrigeration System

Author:Corun Date:2018/06/04

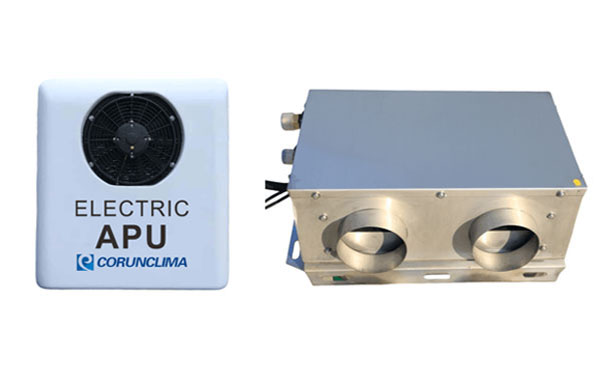

Corunclima boasts providing transport refrigeration unit and electric air conditioners for truck/van/bus of good quality at reasonable rate. Today instead of introducing our products, Corun wants to introduce four main components in refrigeration system which are compressor, condenser, expansion valve, and evaporator and the working principle.

Compressor is the most important component, which is usually called the main engine in refrigeration system. The refrigerant steam is increased from low pressure to high pressure and the continuous flow and transportation of the steam is achieved by the work of the compressor.

The condenser condenses the high-pressure refrigerant steam from the compressor into liquid. During condensation, the heat released by refrigerant steam is taken away by other cooling medium. According to the different types of cooling medium, condenser can be classified into four main categories.

1) The water cooling type: in this type of condenser, refrigerant heat is taken away by cooling water. Cooling water can be used for one time or for recycling. The water cooled condenser can be divided into vertical shell and tube type, horizontal shell and tube type and bushing type according to its different structural types.

2) The air cooling type: in this type of condenser, refrigerant releases heat by air. Air can be natural convection or forced flow by fans. These condensers are used for freon refrigeration units, which is normally applied in the areas where there is insufficient water supply.

3) The water air cooling type: in this type of condenser, the refrigerant is cooled by water and air at the same time, but mainly depends on the evaporation of the cooling water on the surface of the heat transfer tube. A large amount of heat is absorbed from the side of the refrigerant as the latent heat of water vaporization. The effect of the air is mainly to accelerate the evaporation of water. So this type of condenser has very little water consumption. For the air drying areas with insufficient water supply, this condenser is the best choice.

(4) The evaporation – condensation type: in this type of condenser, the cold effect produced by the evaporation of the refrigerant in another refrigeration system is used to cool the refrigerant steam on the other side of the heat transfer wall and promote the condensation and liquefaction of the latter.

The expansion valve plays the role of throttle and depressurization. When the high-pressure refrigerant liquid after condensers passes through the throttle valve, the pressure is dropped due to the obstruction, causing the vaporization of some refrigerants liquid and absorbing the latent heat of gasification. Its temperature is also correspondingly reduced and become wet steam with low temperature and low pressure, and then goes into the evaporator.

The condensed liquid at low temperature enters into evaporator and heat exchange with outside air is carried out here. The heat is absorbed by air to achieve the effect of refrigeration. The evaporator is mainly composed of two parts: the heating chamber and the evaporating chamber. The heating chamber provides the heat needed for evaporation, and promotes the vaporization of the liquid. The evaporation chamber completely separates the gas-liquid two phases. The steam produced in the heating chamber has a large amount of liquid foam. After the evaporation chamber in the larger space, the liquid can be separated from the steam by its own condensation or demister.

Below is a refrigeration cycle diagram.

TAG: Refrigeration Components Corunclima

Prev Article:Companies Make Drivers More Comfortable

Next Article:Coolant Confusion Crisis

.png)