Expansion Valve Adjust and Troubleshooting of Truck Air Conditioner

Author:Corunclima Date:2018/01/11

Before adjust expansion valve, make sure cooling malfunction of truck air conditioner is caused by the valve deviated from best position other than shortage of refrigerant, drier blockage, problems on filter, fans, or any other reasons. Moreover, make sure correctness of data from sensor and installation position of which. Sensor should not be positioned under the hose in case of deposited oil or any other influence factors interfere with sensor.

Notices of adjust expansion valve. Adjustment should be conducted when the unit under normal operation condition. As thermometer could not be positioned on the surface of evaporator, the temperature could be measured nearby compressor since inlet pressure of compressor could be treated as saturated pressure of evaporator. Use thermometer to measure the temp of return air hose, and compare which with evaporating temp to confirm overheat degree. On condition overheat degree is too low, rotate adjust screw clockwise (i.e. increase pressure on spring to decrease opening ratio of the valve and further decrease flow volume). Otherwise overheat degree is too high, which caused liquid feed shortage, rotate screw anticlockwise to increase flow volume. Because of thermal inertia of expansion valve sensor leading to delay of signal transmission, next time adjustment should be done after the unit operated normally. Rotate for adjustment shall not above one round and operate speed shall not be too fast.

Adjust procedures

1. Switch off the unit. Extend thermometer into insulate layer nearby return-air inlet of evaporator. Connect pressure gauge to T-junction of compressor low pressure valve;

2. Switch on the unit. Keep compressor operating for 15mins until it operates stably. Indication of pressure and temp should be stable as well.

3. Compare the temp sensed by thermometer, T1, with T2, the temp corresponding with pressure indicated by pressure gauge, the difference between 2 indications is overheat degree.

Expansion valve blockage position

Generally the blockage would happen on drier filter, impurities blocked by the filter and then leading to blockage. At first return air temp and overheat degree will rise, and then the unit would stop operating due to the problem has become much severe. Ice blockage would be seen at the orifice of expansion valve since the temp of this part is lowest of the whole unit and bore diameter is minimum. If the unit stop cooling, the temp of whole unit would rise. Blocked ice would melt and the whole unit returns to normal after that. Ice blockage would happen again once air conditioner for truck starts to cool. Blockage caused by ice is a repeated problem.

Blockage troubleshoot

Regarding block caused by dirt, change the drier filter if the problem is not too severe. If not, clean impurities inside the hose system, and then vacuumize the system and recharge refrigerant. For slight ice blockage. Apply hot compress on the blockage. If not, change the drier filter, and then draw liquid out of the hose system, vacuumize, and recharge refrigerant.

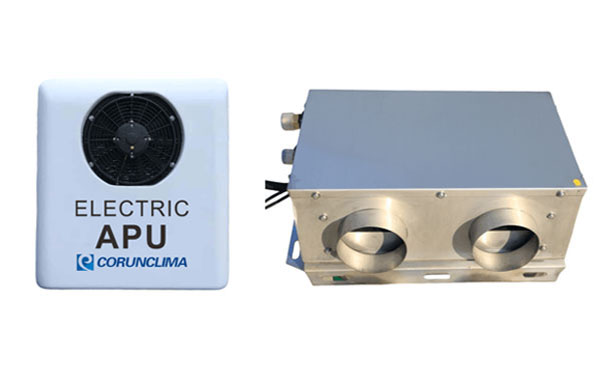

Corunclima electric truck sleeper air conditioner K20BS2 gallery

You are also welcome to Corunclima on Facebook & Google+!

Zhengzhou Corun. Tech. Co. Ltd., & Corunclima

With nearly 20 yrs’ exp. in R&D and manufacture in transport refrigeration unit and all-electric air conditioner, Corunclima gradually evolves from manufacturer to professional consultant of eco-friendly, cost-effective, customizable transport cooling solution.

.png)