Transport Refrigeration Unit Cooling Capacity Computing Theory

Author:Corunclima Date:2018/02/14

Properly choose model of transport refrigeration unit is on one hand to ensure sufficient cooling capacity for temperature-sensitive cargo inside container and prevent extra fuel cost on excessive cooling capacity on the other. Factors deciding cooling capacity include category of target cargo, container size, thermal conductivity of panel, set temperature for reefer unit, and geographical and climate factors. The formula below will be used to calculate cooling capacity:

P= K×Ms×T(int. T-ext. T)×1.75

Letters for multipliers above separately stand for:

P- Cooling capacity of transport refrigeration unit, or heat exchange by applying refrigerated container or air leak, the unit for which is W;

K- Heat conductivity of panel, the unit for which is W/m2k;

Ms- Mean surface area of container, the unit for which is ㎡, the formula below may take to calculate this factor

Ms=

Int.s- total area of container internal surface

Ext.s- total area of container external surface

Int.T- Lowest temperature inside refrigerated container (Celsius degree)

Highest temperature inside heating container (Celsius degree)

Ext.T- Highest temperature outside refrigerated container (Celsius degree)

Lowest temperature outside heating container (Celsius degree)

1.75- minimum safety factor for transport refrigeration unit model selection according to ATP agreement

Parameters in the formula above may also need to take factors below into consideration:

|

Non-precooling cargo |

Required Temp (℃) |

Frozen cargo |

Required Temp (℃) |

Chilling cargo |

Required Temp (℃) |

|

Compressed or ripe cheese |

+10 |

Meat

|

-10 |

Meat |

+7 |

|

Animal fact except butter |

+10 |

Eggs, poultry, animal viscera, rabbit meat

|

-12 |

Butter, cheese |

+6 |

|

Rhizome

|

+7/8 |

Butter, edible fat, cheese |

-14 |

Processed milk |

+6 |

|

Fruit & vegetables |

+4/6 |

Seafood |

-18 |

Unhandled cooked meat |

+6 |

|

Flowers |

+4/6 |

Frozen food |

-18 |

Refrigeration-processed eggs |

+6 |

|

|

|

Medical organs |

-18 |

Raw milk, yoghurt, fresh cheese, cheese |

+4 |

|

|

|

Ice & ice cream |

-25 |

Poultry, rabbit meat |

+3 |

|

|

|

|

|

Animal viscera |

+3 |

|

|

|

|

|

Meat & packaged cooked meat |

+3 |

|

|

|

|

|

Pastry, dessert, egg products |

+3 |

|

|

|

|

|

Live fish, shellfish, and crusta |

+2 |

Safety Factor

Safety factor in ATP agreement is 1.75. However in consideration of various factors leading to cooling energy lost, higher safety factor is recommended to be chosen:

Container with working condition under 0℃: 4.5

Container with working condition under -20℃: 2.5

Factors above have included all applications as well as thermal insulation capacity decrease of container caused by long-time usage in consideration.

Door Open Frequency of Container

On condition refrigerated vehicle operates in urban area and frequent door open is needed, quantity of cooling energy lost is large and this factor should be considered when choosing safety factor. Safety factors mentioned above are applicable to the condition of 20 times open frequency within 8 hours, the open duration lasts for 5 minutes. If open frequency is higher, cooling capacity of transport refrigeration unit should increase 5% with each 10 times’ open frequency added.

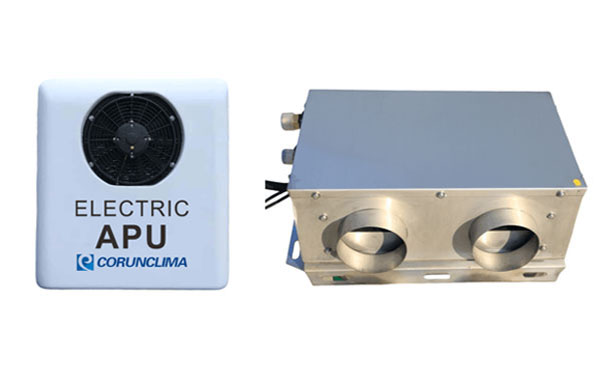

Corunclima integrated standby truck refrigeration unit V650FE gallery

You are also welcome to Corunclima on Facebook & Google+!

Zhengzhou Corun. Tech. Co. Ltd., & Corunclima

With nearly 20 yrs’ exp. in R&D and manufacture in transport refrigeration unit and all-electric air conditioner, Corunclima gradually evolves from manufacturer to professional consultant of eco-friendly, cost-effective, customizable transport cooling solution.

.png)