What to do if the suction pressure of truck refrigeration is too low

Author:Corun Date:2021/05/07

In the pharmaceutical, food and other industries, refrigeration units are common equipment, providing reliable protection for various low-temperature environments such as pharmaceuticals. In recent years, with the continuous development of my country's pharmaceutical industry and the continuous improvement of production, logistics and transportation requirements, the refrigeration unit market has ushered in a good room for development, and through continuous improvement and upgrades, it provides pharmaceutical companies with higher quality refrigeration units. equipment. However, in the process of using the refrigeration unit, even if the user purchases a regular brand, there are no major faults, but small faults often occur from time to time. The user needs to understand the common faults of the equipment and the corresponding solutions to ensure that the equipment can continue to operate.

It is understood that when many users are using refrigeration units, they often find that one day the cooling effect is suddenly worse than before, or there is no cooling. What is going on? According to the industry, the poor cooling of the refrigeration unit means that the suction pressure of the equipment is too low.

So, what caused the low suction pressure of the refrigeration unit? How should users solve it? In this regard, some manufacturer’s technicians said that in fact, there are many reasons for the low suction pressure of the refrigeration unit, including the refrigerant filter clogging the valve, not fully opening, insufficient refrigerant charging, etc. The following briefly introduces common faults and their Solution.

Fault 1: The refrigerant filter is clogged. The refrigerant filter has an important filtering function and should be kept unblocked. If clogging occurs, the filter needs to be cleaned or replaced regularly.

Fault 2: Improper adjustment of the expansion valve or failure. If this phenomenon occurs, it is recommended to immediately adjust the correct or eliminate the fault, and replace it if necessary.

Fault 3: The refrigerant liquid outlet valve of the condenser is not fully opened. It is reported that if the refrigerant liquid outlet valve of the condenser is not opened safely, the refrigeration unit will produce a situation where the suction pressure is too low. At this time, the valve should be fully opened.

Fault 4: The amount of water passing through the evaporator is insufficient. In this case, the cooling capacity will also decrease and the cooling effect will be poor. The user should check the water pump and water valve in time.

Fault 5: Excessive lubricating oil circulates in the chiller refrigeration system. If you find that there is a lot of lubricating oil in the refrigeration system, you should find out the reason at this time and reduce it to an appropriate value.

Fault 6: When the inlet water temperature of the evaporator is too low, the cooling effect is not good. The set value of the inlet water temperature should be increased.

Fault 7: The amount of water passing through the evaporator is insufficient. In this case, the cooling capacity will also decrease, and the cooling effect will be poor. The user should check the water pump and water valve in time.

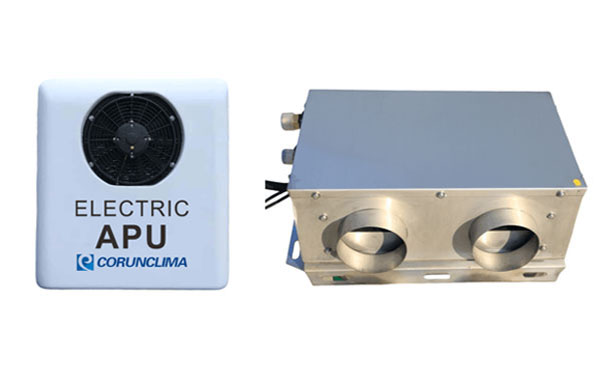

Prev Article:Electric APU installed on Volvo trucks

Next Article:Van refrigeration units shipped to UAE

.png)